Description

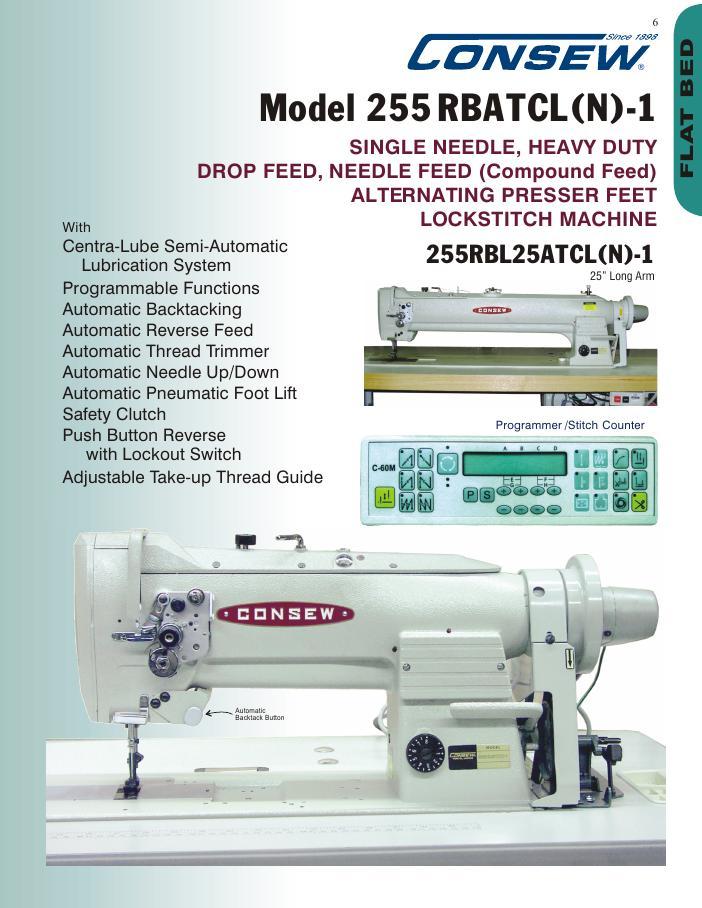

Consew 255RBATCL(N) Fully Automatic Heavy Duty Single Needle Triple Feed Drop Feed Needle Feed and Alternating (Walking) Presser Feet Lockstitch Sewing Machine With Table and Servo Motor

With: Centra-Lube Semi-Automatic Lubrication System, Programmable Functions, Automatic Backtacking, Automatic Reverse Feed, Automatic Thread Trimmer, Automatic Needle Up/Down, Automatic Foot Lift, Safety Clutch, Push Button Reverse with Lockout Switch, Adjustable Take-up Thread Guide

MACHINE APPLICATIONS:

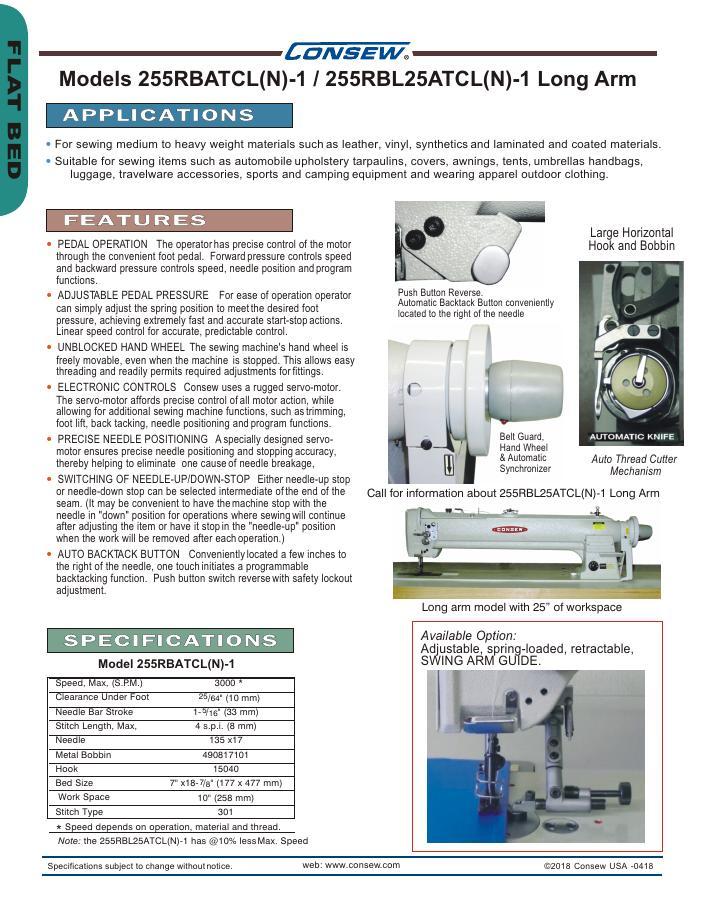

- For sewing medium to heavy weight materials such as leather, vinyl, synthetics and laminated and coated materials.

- Suitable for sewing items such as automobile upholstery tarpaulins, covers, awnings, tents, umbrellas handbags, luggage, travelware accessories, sports and camping equipment and wearing apparel outdoor clothing.

MACHINE FEATURES:

- PEDAL OPERATION The operator has precise control of the motor through the convenient foot pedal. Forward pressure controls speed and backward pressure controls speed, needle position and program functions.

- ADJUSTABLE PEDAL PRESSURE For ease of operation operator can simply adjust the spring position to meet the desired foot pressure, achieving extremely fast and accurate start-stop actions. Linear speed control for accurate, predictable control.

- UNBLOCKED HAND WHEEL The sewing machine's hand wheel is freely movable, even when the machine is stopped. This allows easy threading and readily permits required adjustments for fittings.

- ELECTRONIC CONTROLS Consew uses a rugged servo-motor. The servo-motor affords precise control of all motor action, while allowing for additional sewing machine functions, such as trimming, foot lift, back tacking, needle positioning and program functions.

- PRECISE NEEDLE POSITIONING A specially designed servo-motor ensures precise needle positioning and stopping accuracy, thereby helping to eliminate one cause of needle breakage.

- SWITCHING OF NEEDLE-UP/DOWN-STOP Either needle-up stop or needle-down stop can be selected intermediate of the end of the seam. (It may be convenient to have the machine stop with the needle in "down" position for operations where sewing will continue after adjusting the item or have it stop in the "needle-up" position when the work will be removed after each operation.)

- AUTO BACKTACK BUTTON Conveniently located a few inches to the right of the needle, one touch initiates a programmable backtacking function. Push button switch reverse with safety lockout adjustment.

MACHINE SPECIFICATIONS:

- Number of Needles: 1 (Single)

- Feeding Mechanism: Walking Foot

- Workspace: Standard Workspace

- Standard or Full Function: Auto Trimming, Backtack, Reverse

- Speed, Max (S.P.M.): 3000

- Clearance Under Presser Foot: 25/64" (10mm)

- Stitch Length: 4 s.p.i. (8mm)

- Work Space: 10" (258mm)

- Needle: 135 x 17

- Bobbin: 15041 Pre-Wound S or U

- Bed Size: 7" x 18 7/8" (177mm x 477mm)

- Stitch Type: 301

- Needle Bar Stroke: 1 5/16" (33mm)

- Hook: 15040

THE ADVANTAGES OF A SERVO MOTOR:

- Silent and use up to 90% less power than clutch motors

- 1/3 lighter than clutch motors

- With a flick of the switch you can reverse motor rotation

- No parts to wear out or adjust

- Lightweight, precise, and reliable

Thanks to the speed control feature, most users find the machine easier to use. Both beginner and advanced sewers find this feature helpful when stitching projects that require high-speed and precise stitching.